Automatic Sealing Machine | Industrial Production Line Sealers

PH-22 / 66 Series

Conform to international CE safety regulations and ISO 9001 quality standards.

Automatic production line container sealing machine for all kinds of cups and trays, 15 cycles per minute in cut & seal, the production capacity can be custom-made according to your requirements. Can be equipped with various optional functions to complete your production line, such as cup/tray denester, filling system, date coders and so on. Save your labour costs and increase the efficiency of production at the same time.

- Overview

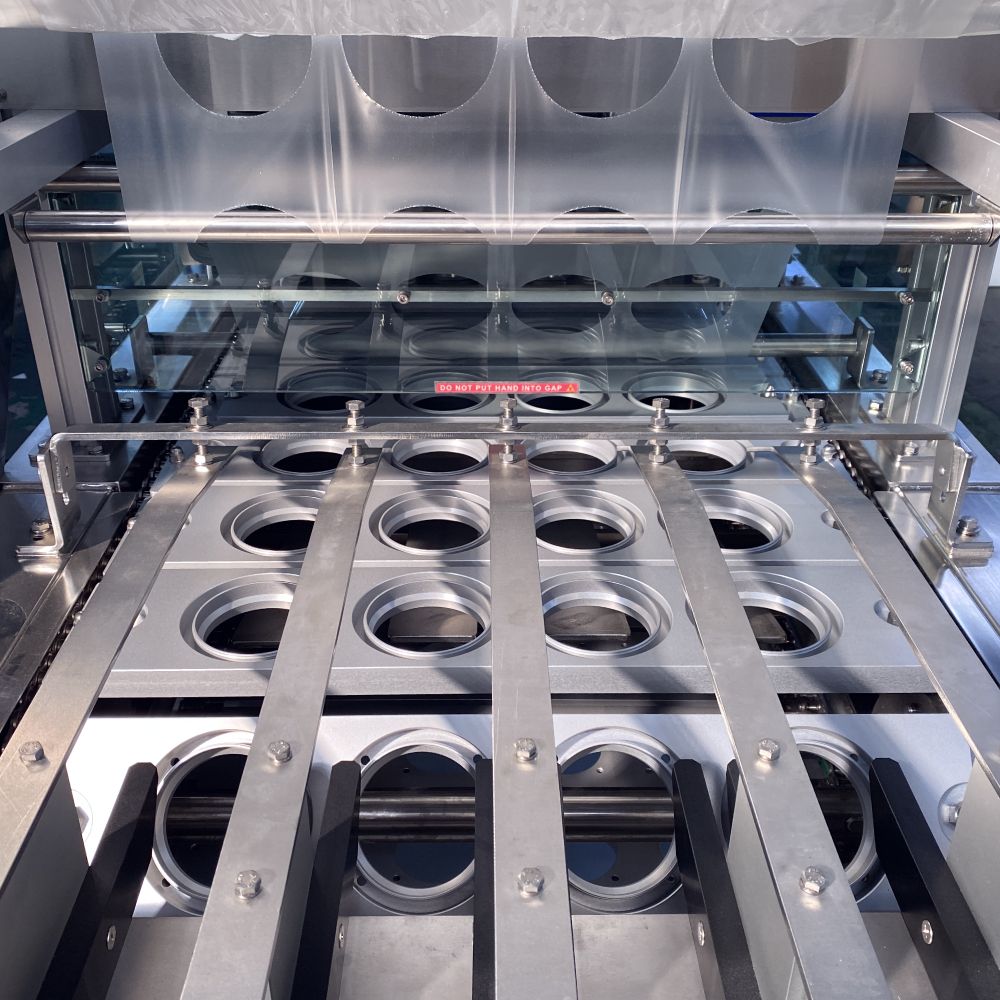

PH-22 / 66 series are production line container sealer machines

For all types and materials of cups and trays. These two series are aimed at high production numbers with accurate cup/tray positioning. Different materials of printed and unprinted films can be used in the same machine, no need to replace any accessories. Pre-cut films are also available.

Applications

- Suitable for food factories, food processing plants, packing houses, packing plants, supermarkets, convenience stores, etc.

- For sealing water cups, beverages, yogurts, puddings, tofu, meal boxes, frozen food, microwave meals and so on.

- Specs

Features

- Touch Screen Panel with PLC Control System. (remote connectivity available)

- Error Message Display.

- Protection Rank: IP 65.

- Stainless Steel Frame.

- Anodized Aluminum Mold.

- Teflon Coated Heater.

- Film Rewinding System. (printed and unprinted films are both available)

- Can be used with different materials of films, such as plastic films, paper films and aluminum films.

- Maximum sealing area up to 740mm*220mm, bigger size can be customized.

- Multiple Safety Design.

- Up to 8 lines, higher production capacity can be customized.

Optional Functions

- Cup/Tray Denester.

- Filling System.

- Date Printer. (available with English texts, dates, codes)

- Gas Flushing System. (Modified Atmosphere Packaging)

- Precut Film Feeding System.

- UV Light Sterilizer.

- Mold Washing System.

- Capping System.

Model Machine Size

W x D x H mmCapacity (pcs/hr) Power (V) Max Container Size

L x W x H mmPH-22S1 2000 x 660 x 1700 900~1800 3 phase, 220/380/415/480 220 x 170 x 100 PH-22M1 2000 x 930 x 1700 900~5400 440 x 220 x 100 PH-22L1 2000 x 1200 x 1700 900~7200 740 x 220 x 100 PH-66SS1 2500 x 660 x 1700 900~1800 3 phase, 220/380/415/480 170 x 220 x 100 PH-66S1 2500 x 850 x 1700 900~3600 360 x 220 x 100 PH-66M2 2500 x 1040 x 1700 1800~7200 260 x 220 x 100 PH-66L2 2500 x 1230 x 1700 1800~7200 355 x 220 x 100 - Videos

- E-Catalog

- Related Products

Automatic Sealing Machine | Industrial Production Line Sealers | Advanced Packaging Solutions with Food-Safe Certifications | Phoenixes Multi Solutions

Established in Taiwan since 2000, Phoenixes Multi Solutions Inc. specializes in high-quality, customizable packaging solutions. Our comprehensive product range includes Automatic Sealing Machine | Industrial Production Line Sealers, cup sealers, tray sealers, sealing films, sachet packaging machines, production line sealers, rotary sealers, fructose dispensers, and powder dispensers. With multilingual support in Chinese, English, and Spanish, we offer global accessibility and ensure exceptional customer satisfaction. Certified for food safety and quality standards, Phoenixes Multi Solutions Inc. is a supplier of innovative packaging solutions in Taiwan and international markets, dedicated to delivering secure and reliable products.

With more than 20 years of professional experience in food packaging, offering a wide range of sealer machines, sealing films, fully automatic sealing equipment, and automatic sachet filling and packaging machines. We are also proficient in planning comprehensive packaging solutions to enhance the quality of our customers' product packaging."

Phoenixes delivers advanced packaging solutions, specializing in cup sealers, tray sealers, and sealing films. Using cutting-edge technology, we meet each customer’s unique packaging requirements with precision and reliability.