Troubleshooting For Cup Sealing Machines

Q: Is any maintenance required for my sealing machine?

A: Yes, we suggest cleaning the machine daily and lubricate the machine weekly or monthly depending on how frequently you use the machine. A proper maintenance will keep the machine functioning longer and reducing abrasion.

Please make sure the temperature of machine has cooled down and has been unplugged before daily maintenance. Also, be careful with the sharpness of cuter and moving parts for your safety.

"Kids and non-related personnel are strictly forbidden."

Q: How can I install the sealing films?

A:

Q: How can I adjust the settings on my sealing machine?

A:

Cup sealer setting: P1~P5

- P1: Temperature setting.

- P2: Lock or Open the sealing counter; reset the counter.

- P3: Sealing time.

- P4: Input time.

- P5: Timer for blank films (usually this setting remains “000” if you run by the sensor).

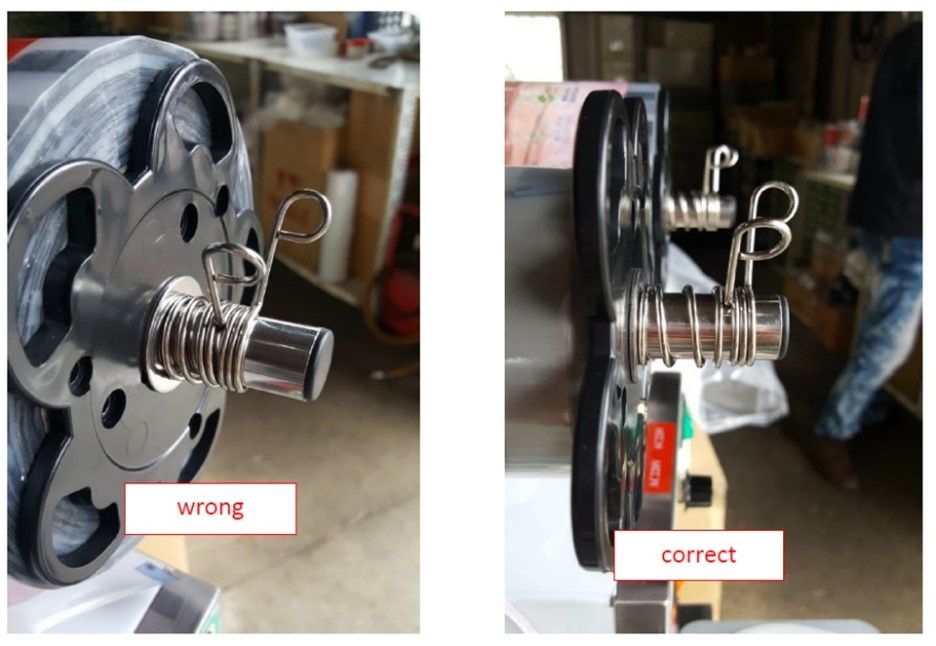

Q: Sealing film keeps breaking.

A: Check if the butterfly clamps are too tightened, Loosen the clamps, re-install the films, and try it again.

Q: Machine seals without rolling the film.

A: If you found the machine seals without rolling the film or the cup is only sealed with a small piece of film, please check if P5 is set 000.

Q: Auto-mode is not working (cups cannot be detected).

A: Normal situation: When the cup is inside the machine, both red and green lights on. When there’s NO cup inside the machine, only green lights on, red light should be off.

Situation 1: When there’s a cup inside the machine, but the red light is not on, it means the sensor is not strong enough to detect the cup. We have to turn the knob clockwise to make the sensor stronger.

Situation 2: When there’s NO cup inside the machine, both red and green light are on, it means the sensor is too strong.

Step 1. Check if the black paint is still in the lower mold.

If no, use the spray paint to make the inner lower mold black. A marker will do also.

Step 2. Adjust the sensibility of the cup input sensor.

Turn the knob counter-clockwise to make the sensor less strong.

Q: Why does the sealer have an error code?

A: The machine buzzes once any malfunctioning and failure are detected.

Please ckeck

Error codes and descriptions🔗

Troubleshooting For Cup Sealing Machines | Reliable Supplier of Container Sealing Machines & Packaging Solutions | Phoenixes Taiwan

Established in Taiwan since 2000, Phoenixes Multi Solutions Inc. specializes in high-quality, customizable packaging solutions. Our comprehensive product range includes cup sealers, tray sealers, sealing films, sachet packaging machines, production line sealers, rotary sealers, fructose dispensers, and powder dispensers. With multilingual support in Chinese, English, and Spanish, we offer global accessibility and ensure exceptional customer satisfaction. Certified for food safety and quality standards, Phoenixes Multi Solutions Inc. is a supplier of innovative packaging solutions in Taiwan and international markets, dedicated to delivering secure and reliable products.

With more than 20 years of professional experience in food packaging, offering a wide range of sealer machines, sealing films, fully automatic sealing equipment, and automatic sachet filling and packaging machines. We are also proficient in planning comprehensive packaging solutions to enhance the quality of our customers' product packaging."

Phoenixes delivers advanced packaging solutions, specializing in cup sealers, tray sealers, and sealing films. Using cutting-edge technology, we meet each customer’s unique packaging requirements with precision and reliability.